- 15” 4:3 high-resolution touch screen (resolution XGA 1024x768)

- CPU PC: AMD Embedded GX 420 CA 2GHz, with 4Gb of RAM

- CPU CNC: Amd LX-LX800 500MHz, with 128Mb of RAM

- FPGA integrated logics, surface mounting, fiber optic

- 24Vdc 100W max power supply

- Ergonomic aluminium housing, with a panel suitable for machine operational selector-switches and push-buttons(OPTION)

- 2.5” Hard disk drive 20GB or more

- Pre-set for standard pc keyboard and mouse (ps2 standard connectors)

- 2 serial ports rs-232

- 2 USB port for memory stick

- 1 ethernet port

- 1 can open port

- Fiber optic interface

- Local area network

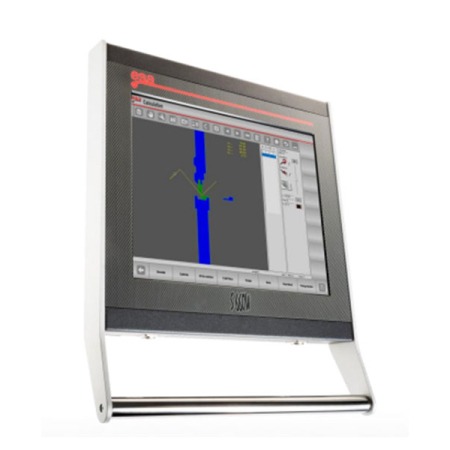

S650 W CNC Control

S650 W CNC Control for Press Brakes and Shears by ESAutomation (ESA)

The top performances in the compact class. 15” 4:3 high-resolution touch screen

No limit in both performances and flexibility. Designed to control machines up to eight axes . The wide screen allows excellent comfort for the operator enhancing the advantages of a full graphic interface. The powerful built-in PC allows having on the machine a real 3D cad cam (metallix, radan, esa).

Includes Automatic bending sequence calculations to reduce the wastage of material. Material Data Base for predictive compensation is available as an option. Crowning correction in degrees. Dynamic crowning is available to grant the perfect bend linearity.

Direct import of tools shapes (.dxf files) and management of tool library. Tool and die holders’ management.

Direct connection of Mitutoyo protractor and Angle check device to allow in process angle measurement.

To make an enquiry, click below or call us on 01562 744 873 for more information.

- Conventional press-brakes (Mechanical and Hydraulic), synchro Hydraulic press-brakes, servo controlled hydraulic single cylinder press-brakes, electrically driven press-brakes, tandem press-brakes

- Hydro-mechanical press-brakes American style

- Interactive 2d graphic editor for work-pieces and tools data entry

- 2D graphic display of machine frame, work-piece and tools

- 2D automatic identification of the best bending sequence

- Programming of the axes positions in tabular mode with automatic syntactical checks, automatic calculation of the r, and z and A positions and of the bending and crowning tonnage

- Windows® like user interface

- Complete off-line programming on a standard pc

- IEC 61131-3 plc programming language with function utilities either written in “IL” or “C” language, are available for manufacturers

- Customizable alarm messages

- Hämmerle press-brakes

MTL Engineering Ltd

Unit A3, Rickets Close,

Firs Industrial Estate,

Kidderminster,

West Midlands,

DY11 7QN

phone: 01562 744873

email: [email protected]

Useful Links

2025 © MTL Engineering Ltd

All Rights Reserved | Design by eSterling